Production Monitoring Display Led display board, Display board, Display

Plastics industry case study. "Clariprod is simply the best real-time production monitoring system for the plastics industry, especially injection molding. Accurate. Affordable. Easy-to-use.". - Frank Desrosiers, President, and Co-Owner of Windmill Plastics. See some concrete results of using multiple Clariprod controllers in an injection.

Display Systems Production Monitoring Systems Manufacturer from Delhi

Flat pack furniture production monitoring - a case study. The task Decorative Panels Furniture asked us to design and build production monitoring displays for each of their flat-pack component production lines. They wanted a system which was easy to install and use. It also needed to be able to withstand the dusty conditions created by the.

Production Monitoring Software

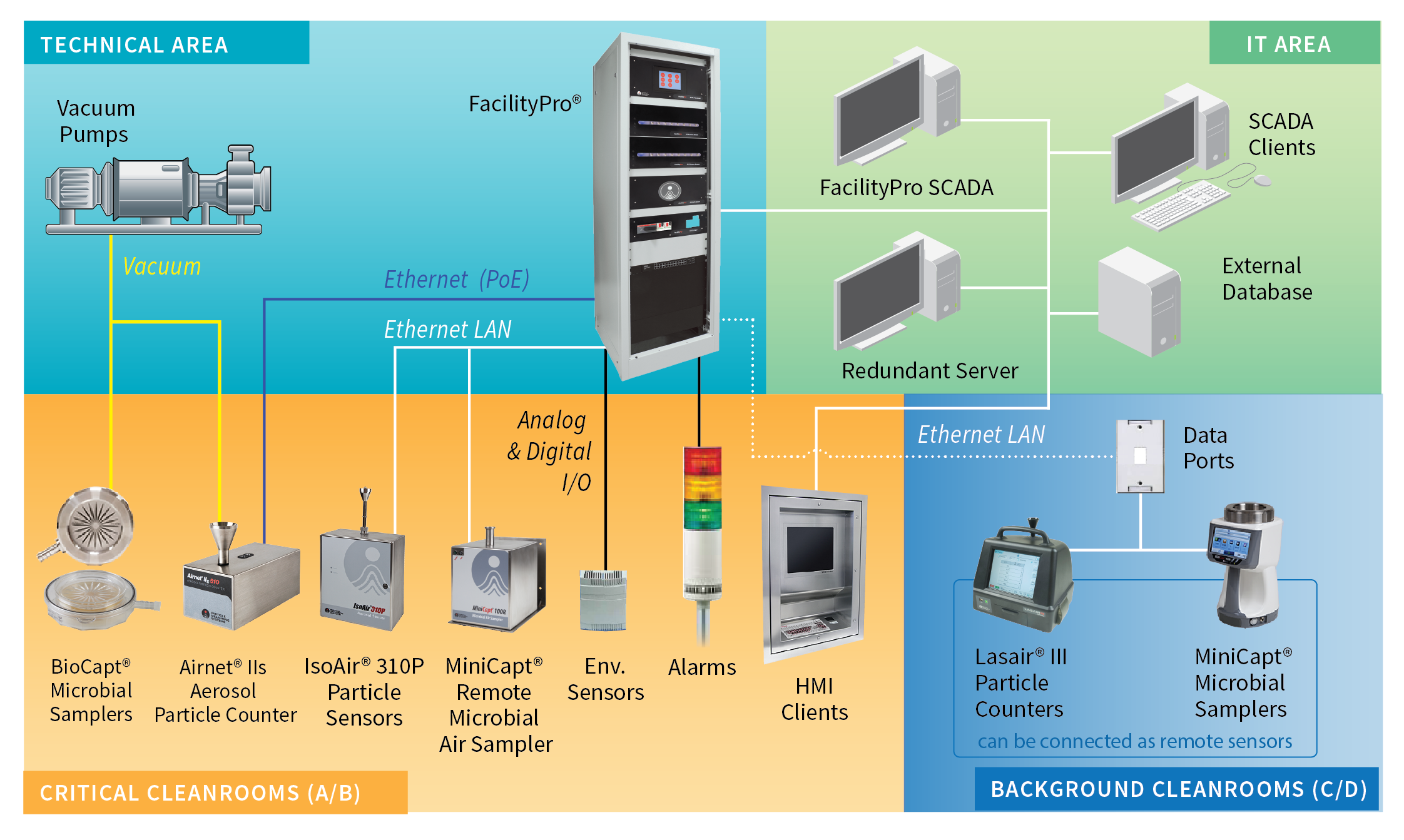

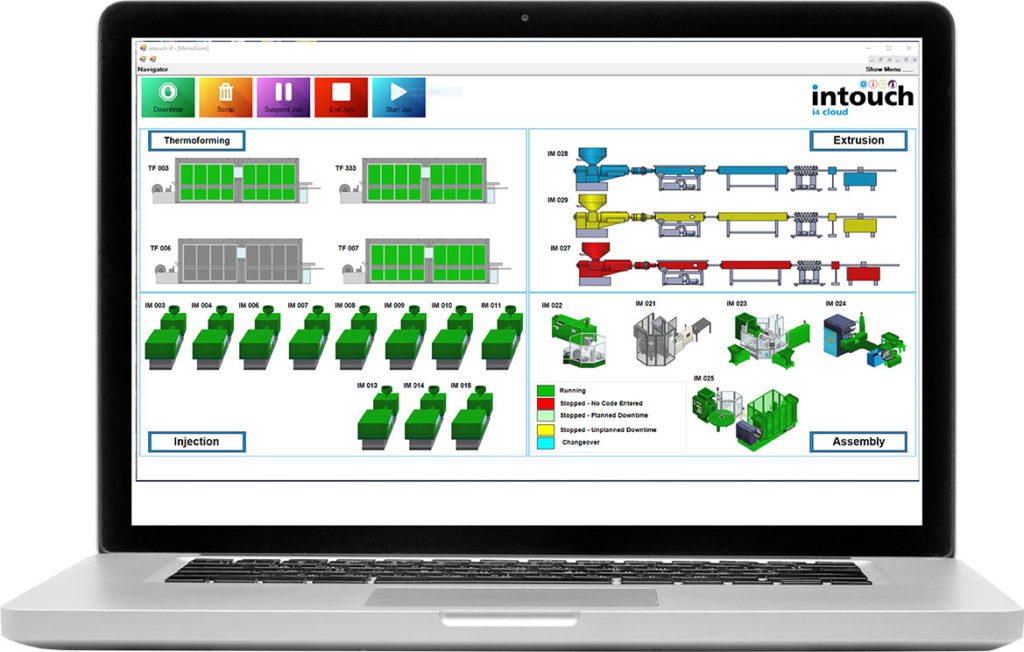

Production Monitoring Platform. Collect data from to any machine by connecting the MachineMetrics Edge to the ethernet port of the control. Software on the edge processes data from the machine in real-time and streams the data securely to the MachineMetrics cloud. Identify and Resolve Downtime. View and manage the status of your machine assets.

Sheet Metal Rectangular Production Monitoring Display System at best price in Vadodara

DELMIAWorks (formerly IQMS)' RealTime™ Production system takes plant management to a higher level. Completely embedded with DELMIAWorks, DELMIAWorks' RealTime™ manufacturing monitoring and data collection tools track all aspects of your production immediately as parts are being made and applied to the shop orders, automatically updating DELMIAWorks manufacturing ERP software modules with.

CNC Machine Monitoring & OEE Software MachineMetrics

Digitally Track Production. Say goodbye to dry-erase whiteboards! Plex Production Monitoring, powered by Plex Mach2, provides seamless connectivity to and from machines on the plant floor. With our out-of-the-box software you've got access to production visibility fast without draining resources.

Easy production monitoring system dashboard for a production hall

The same two sensors used for a production counter can generate dozens of insightful metrics right out-of-the-box when connected to a production monitor. Use a production monitor to display a simple set of real-time metrics on the plant floor (e.g., Target, Actual, Efficiency, and Down Time) and to deliver key historical metrics and analytics.

Wall Mounted Railways Production Monitoring Display System, 10 mm, Resolution 1080x780P at Rs

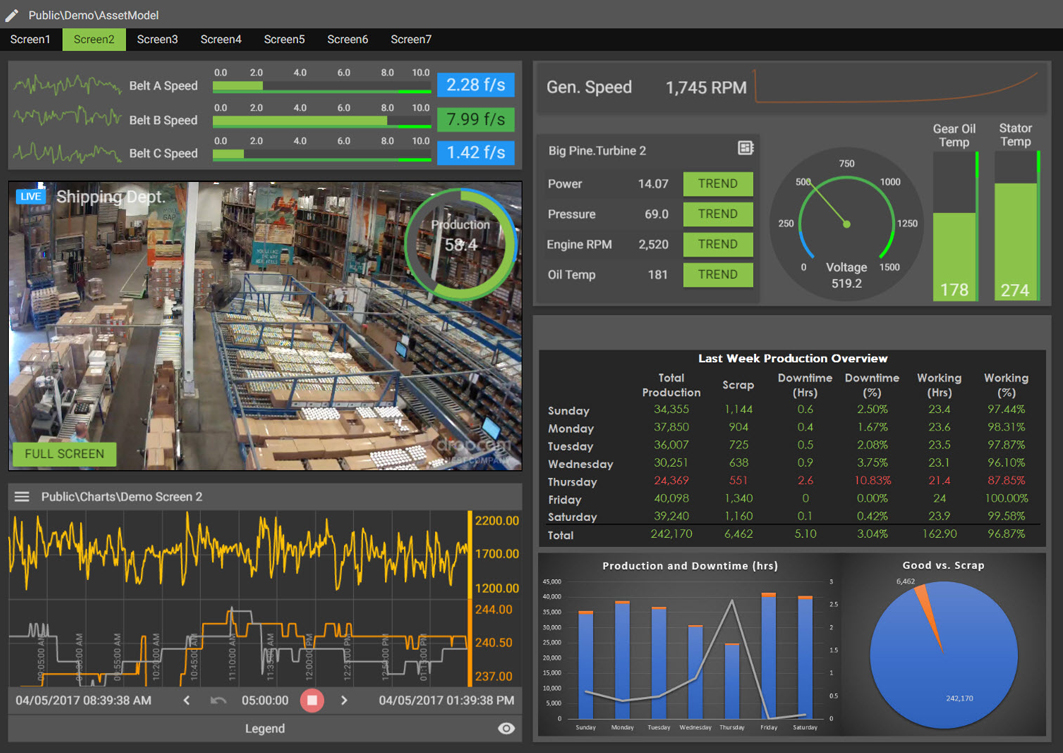

Production and downtime tracking is part of the real time manufacturing process. For example, our OEE software performs data collection from integrated systems and equipment and offers additional user data. The software features include quality monitoring, determining root causes with downtown tracking, automated alerts, notification, etc.

Facility Monitoring Systems (FMS) EMS Particle Solutions

Such a system indicates current and historic OEE (Overall Equipment Effectiveness) and displays it within dashboards, available on phones and tablets, laptops or bigger shop floor monitors (SFM). It is used for reporting to the managers and for coherent communication anong production employees.. On top of that, production monitoring systems.

Visualize Getting More From Existing Equipment Canadian Metalworking

Advanced real-time manufacturing monitoring systems can be powerful tools for process monitoring. They are also a source of data insights that managers can use, analysts, and systems across the whole organization. Analyzing production data and working out process improvements takes time. It is one of the reasons why some production companies.

Best System Monitoring Tools for Windows Environments of 2021

Establish your baseline and connect production line monitoring software directly to PLC data. Unlike data loggers and add-on sensors, LineView production line monitoring solution connects automatically to your PLCs. We'll conduct an initial site audit to optimise your connection, identify instant wins and prioritise which efficiency.

Production Monitoring Display System at Rs 16000/unit Kolathur Chennai ID 19206436962

6 examples of manufacturing dashboards to transform your shop floor. 1.) The "Mission Control" Dashboard. "Mission control" dashboards are high-level overviews for keeping the whole team aligned. In this dashboard, we see all of the information we need to get a sense of how production is going on a given day.

Production Monitoring Software GlobalReader

Real-Time Production Monitoring System. XL is the simplest and fastest way to monitor and improve production.. When we installed Vorne displays…the target rate for one of the lines was inadvertently set higher than was planned. A few hours later when the plant manager glanced at the display, he was amazed to see…the line was running at.

Production Monitoring Display Board Compucare Automation Division

Understand downtime, speed, and quality loss. Evocon's production monitoring software allows you to automate downtime, speed loss, and quality tracking. All operators have to do is map reasons to events with a few clicks, giving you the understanding of which issues are most relevant and where to focus your attention.

Production Monitoring System Software Intouch Monitoring

Production monitoring display systems can provide significant value by delivering the right information at the right time - when your plant floor team can still change the arc of the shift. Because operators tend to be focused on specific production lines, there tends to be quite a bit of overlap with machine monitoring at this level.

Real Time Production Monitoring Software Factory & Production Line Monitoring

Award-winning technology and 15-minute setup mean adding powerful remote monitoring to your manufacturing is easy. You can set up Monnit Sensors within 15 minutes. An intuitive PC or smartphone interface simplifies sensor deployment. Get the freedom of 2,000+ ft. through 18+ walls of wireless range thanks to one of the most powerful sensor.

UTILIZATION MONITORING AND ANALYSIS

Data Collection: Central to the monitoring process is the act of data collection.Contemporary production monitoring systems utilize an array of sensors throughout the manufacturing environment. Ranging from temperature sensors to machine vibration detectors, these instruments persistently collect raw data, encapsulating every facet of the manufacturing procedure.