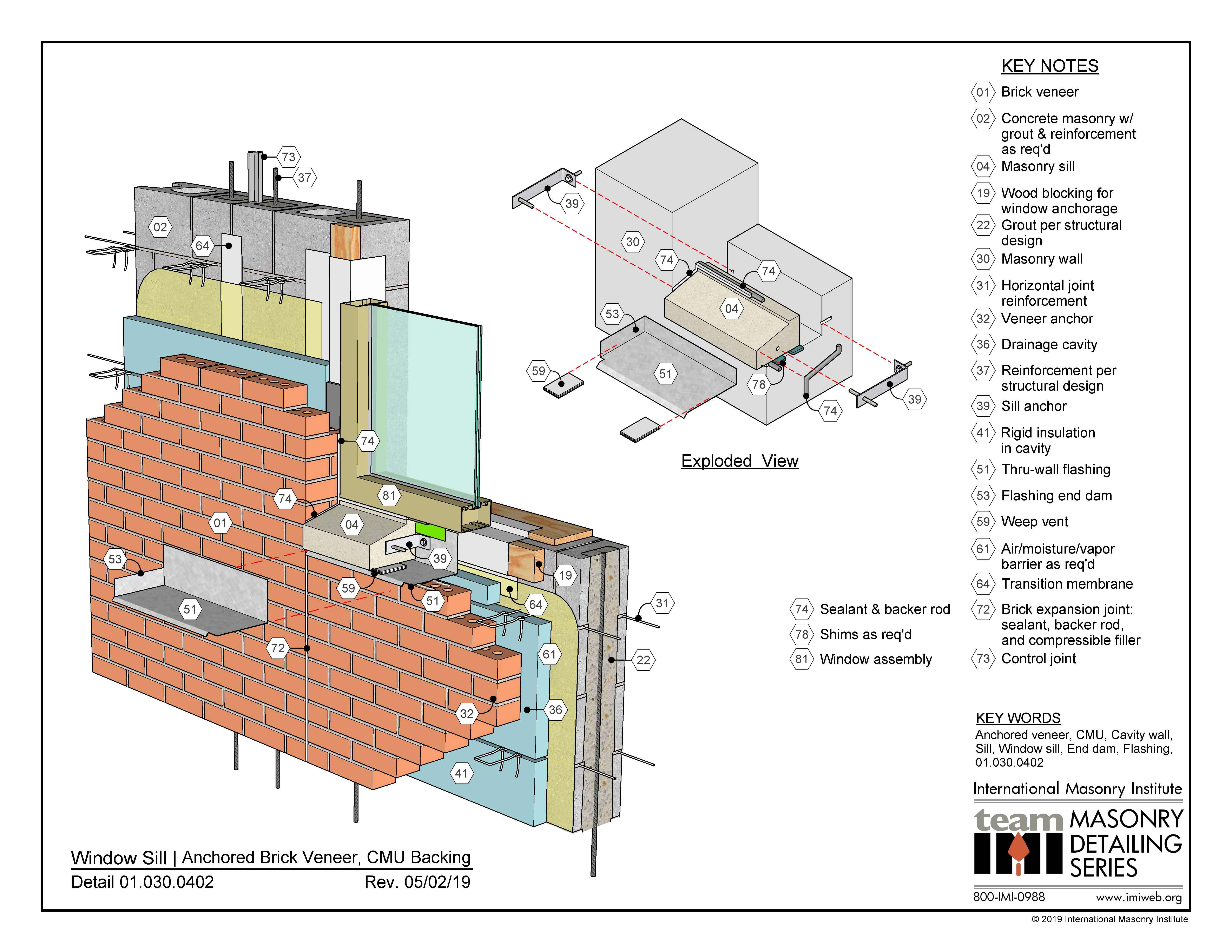

01.030.0402 Window Sill Detail Anchored Brick Veneer, CMU Backing

entire sill and up 6" of each jamb of rough opening scale: not to scale revision date: 4/19/2022 drawing: a36 window sill detail residential wood frame structure w/ vinyl siding dupont™ flexwrap™ install tower ® residential sealant or recommended sealant (and backer rod as necessary) around the window opening at the interior. it is also

Concrete Window Sills 50mm Swansea Premier Concrete Products

The process of building a basement requires 3 costly visits from a team of concrete trucks; once to pour a footing, again to pour walls, and a third time to pour a basement floor. For every ton of concrete produced, one ton of greenhouse gases is released into the atmosphere. Once a basement foundation is completed, a subfloor must be built on top.

Window Sills Concrete Specialists Moore Concrete

Design Details Design » Architectural Resources » Design Details This section provides information and resources related to design of precast concrete systems, as well as integration of precast with other systems. Connection Details (Adobe PDF File) Joint Details (Adobe PDF File) Interface Details - Window, Floor and Roof (Adobe PDF File)

Concrete Window Sills 50mm Swansea Premier Concrete Products

Topping the cabinets along the walls and the window sill are dark grey 3" thick concrete counters. When the folding windows are open, the sill becomes a 15" deep serving bar for outdoor entertaining. For ergonomics - the dishwasher and microwave were raised to 42" and 54" comparatively.

Window Sills Precast Concrete Sanderson Concrete

Window Sills Manufacturing windowsills for over 3 decades, Sanderson Concrete has become the gold standard for architectural precast concrete trim. With precast on virtually every corner of every city in the Lower Mainland and throughout BC, Sanderson Concrete produces thousands of windowsills, lintels, caps and coping annually.

Window Sills Allen Concrete

entire sill and up 6" of each jamb of rough opening scale: not to scale revision date: 4/11/2022 drawing: a56 window sill detail residential wood frame structure w/ masonry veneer dupont™ flexwrap™ through-wall flashing great stuff pro™ window concrete sill w/ drip edge & door polyurethane foam sealant, or recommended minimally expanding

02.010.0401 Sill Detail Single Wythe Block International Masonry

Window sill detail - wood frame structure with masonry veneer (PDF | DWG) Window head detail - wood frame structure with masonry veneer. Concrete column transition (method 2) (PDF | DWG) Parapet wall (PDF | DWG) Shelf angle (PDF | DWG) Wall penetration (method 1) (PDF | DWG) Back to top

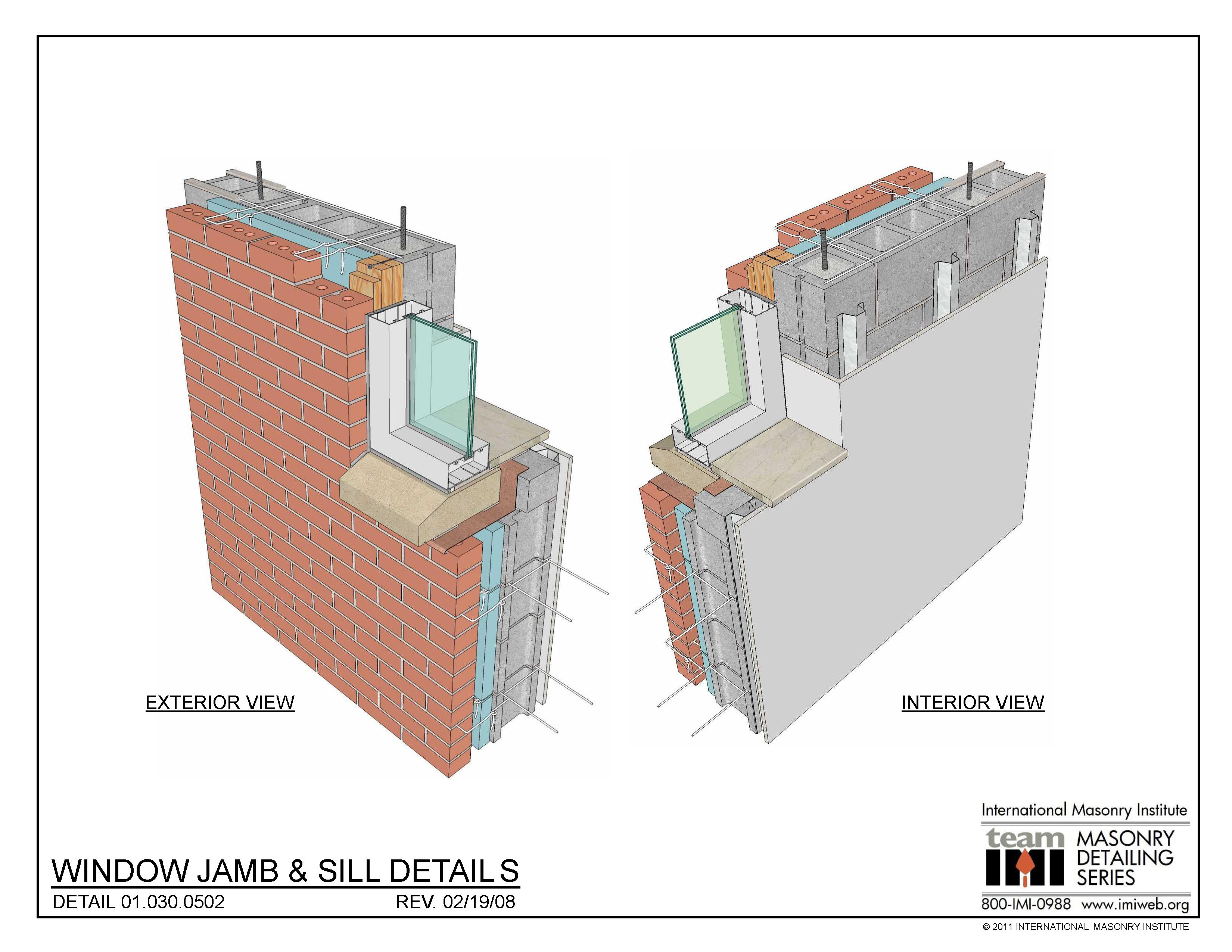

01.030.0502 Window Jamb & Sill Details International Masonry Institute

This detail shows an 8" (nominal) split face concrete masonry (CMU) wall, window sill condition. Flashing is provided below the masonry sill, returning vertically at the end termination to form an end dam. Ladder-type horizontal joint reinforcement is placed at 16" o.c. vertically in the wall, or as required. DOWNLOAD DETAIL [PDF] 3D Detail

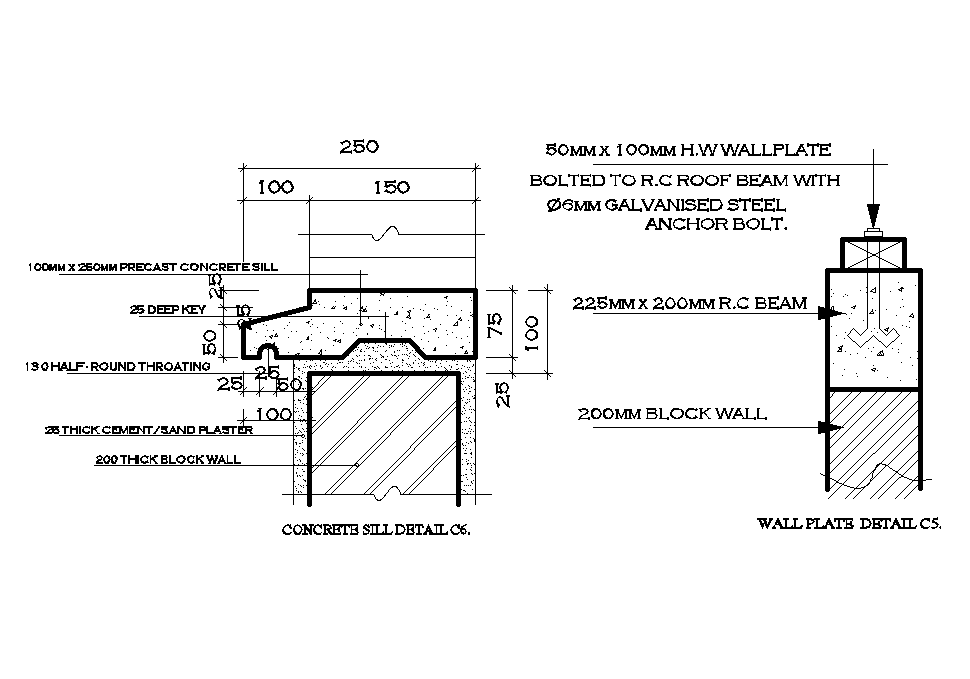

Concrete sill detail is given in this Autocad drawing file. Download

Concrete Window Sills SILLS Precast concrete sills are used below windows, ledges, and transitions. They protect the masonry or stuccowork and provide transition between masonry and other exterior finishes. Sills help to complete your project and are designed with a sloping top to assist with water runoff.

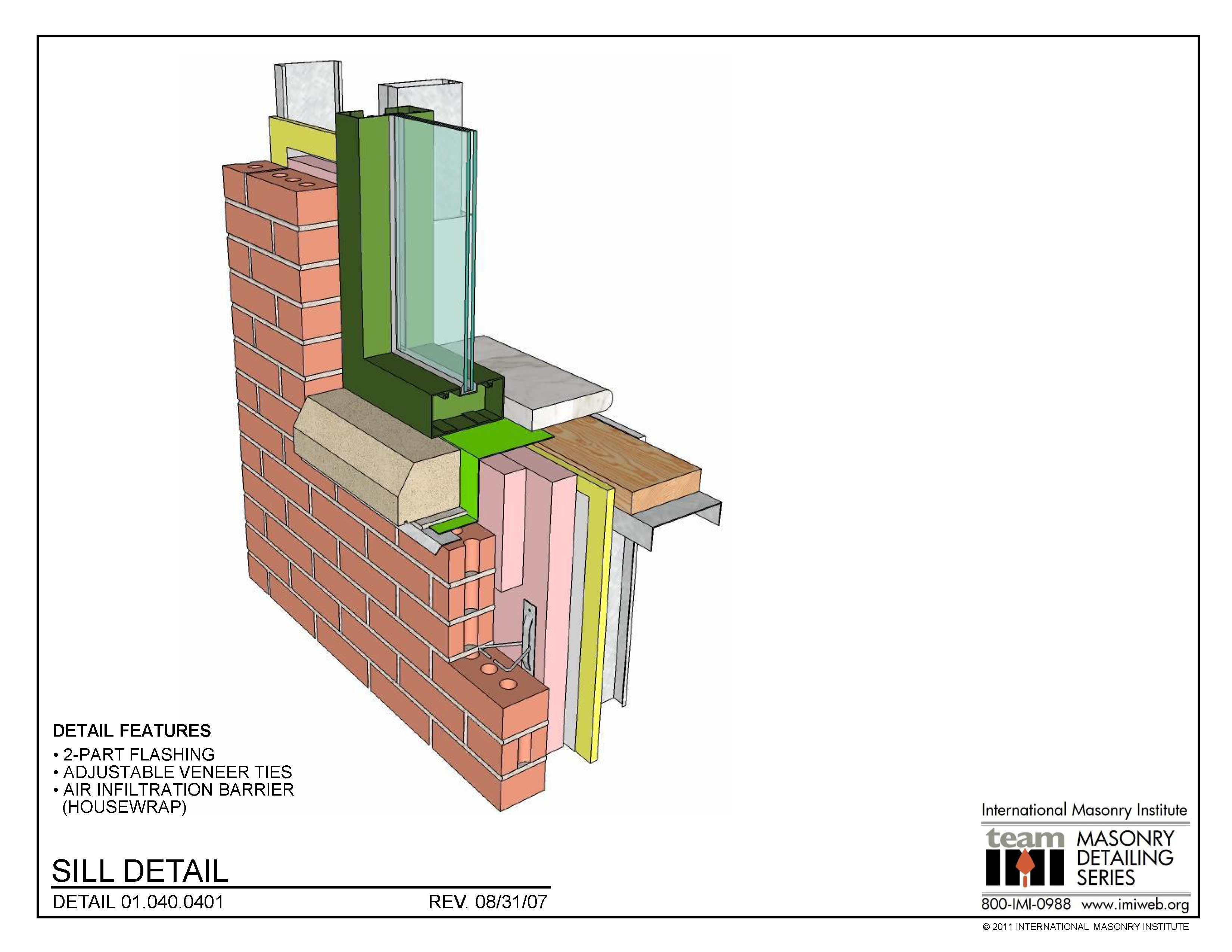

01.040.0401 Sill Detail International Masonry Institute

Key elements of a sill flashing system for a window with a mounting flange that provides adequate protection to inadvertent water entry are provided in Figure 4 and include: Back dam (1) Sloped sill (2) Sill flashing membrane wrapping up the jambs and over the sheathing membrane at the sill (3) Proper lapping of flashing layers and the sheathing.

Masonry wall, Architecture details, Window sill

Key elements of window installation Structure: The building's structure may help in choosing a window style and material type. We will be looking at a modern mixed aluminium and timber window.

Exterior Wall Section at Window Sill ID 113 Materials and

1. Moisture protection. Protecting against water intrusion is arguably the most important function of a window sill. If water gets into your house, it can have detrimental effects on the foundation. Mold can build up, your drywall can rot, and in extreme cases, your home can suffer structural damage.

Sills Williams Concrete Products

Window Surround Window Sill, Cap and Keystone, Precast Trim Bernardi Precast offers a selection of concrete window sills, wall and post caps, keystones and precast concrete.

Window Sills Precast Concrete Sanderson Concrete

We also install custom-formed silica concrete window sills, with a variety of other finishes to match original sills on the house. Arches and lintels are structural supports above a window, doorway or opening. Over time they can crack or shift, destabilizing the wall above, so special skills are required to repair or replace them.

Typical Window Detail BecoWallform Insulated Concrete Formwork

Detail 2.3a: Precast Window Sill-Wood-Frame Wall 2-7 Detail 2.3b: Flashing/Sill Types 2-9 Detail 2.4: Metal Window Sill/Extruded Aluminum Sill with Rain Deflector 2-11 Detail 2.5: Jointed Precast Window Sill-Brick Veneer 2-13 Detail 2.6: Window/Door Head Brick Veneer 2-17 Detail 2.7: Shelf Angle at Concrete Slab-Brick Veneer/CMU 2-19

DL115 Precast Concrete Slip Sill Typical Details

The function of the cill is to protect the wall below a window, so they are shaped to slope down and project beyond the external face of the wall in order to allow water to run off. It is good practice for the cill to project at least 45mm beyond the face of the wall below and have a drip on the underside of the projection.